Technical details

The decentralized and solar-powered powerhouse is based on a modular mini-container design (Bauhaus building block principle) and consists of at least two interconnected 10-foot container modules, each of which can be completely dismantled.

Energy supply. The electricity generated via photovoltaics ((PV), roof construction with 4.8 – 7.5 kWp) is stored in a container module (low-voltage direct current (LVDC) sodium-ion battery storage, 48 VDC, 35 kWh) and converted to 230 VAC using a hybrid inverter (5 kW connected load). To minimize investment costs and for reasons of sustainability, remanufactured 2nd-life PV modules and B-goods Li:NMC battery storage systems from the automotive industry, which are equipped with a special safety concept developed by Fraunhofer HHI, are preferred. As a rule, 10-15 VoltaMove2Go power packs (2.4 kWh per pack, weight 10 kg, 230 VDC and USB output) are installed in the Powerhouse system. Mobile battery modules for e-mobility supply 48 VDC with 4.8 kWh and weight 20 kg.

Water supply. In a second container module, drinking water is produced using a multi-stage filtration process with sediment, activated carbon and nanofiltration and subsequent UV-C irradiation. The water to be treated mainly comes from collected rainwater, lakes, rivers or well water. The production capacity of the plant is 1,200 – 5,000 liters per day.

Installation

The Powerhouse systems are manufactured and pre-assembled by VoltaMove GmbH in Germany and then installed, assembled and commissioned at the respective installation site in cooperation with VoltaViewAfrica gUG and local partners. The installation is subject to the generally applicable occupational health and safety measures. An internet-based remote monitoring system is available to document the operating parameters and yield values, which enables optimum predictive maintenance and servicing. Additional permits for operation etc. are generally not required, as either collected rainwater, lake/river water or existing well water is used for treatment/cleaning. No electricity is fed into a grid, so the systems are generally not subject to the regulations of local grid operators.

Plant operation and maintenance

The local partners (in The Gambia BenaBena The Gambia, in Tanzania JUMEME Ltd.) are instructed and trained in the function of the systems, the operation of the systems and the necessary maintenance work so that they can monitor the operation after installation and carry out the service and maintenance work on site independently. Training and education are also carried out in cooperation with local universities (e.g. in The Gambia with the University of Applied Science, Engineering and Technology (USET) in Serekunda). An internet-based monitoring system enables the continuous documentation of plant parameters and yields as well as alerts in the event of faults or maintenance requirements.

Warranty

The product warranty for Powerhouse systems is 2 years. In addition, an after-sales service is offered by local partners.

The Powerhouse In ACtion

-

The Watoto wa Africa Orphanage

The Watoto Wa Africa orphanage in Mwanza/Tanzania is an institution in great need, as it has no or only irregular electricity and no drinking water. Its only source of water is the collection of rainwater in large tanks. In spring 2023, there was a typhoid epidemic with fatalities. To support the orphanage, VoltaViewAfrica will install a Powerhouse by the end of this year, which will provide electricity and clean drinking water for the orphanage. This project is supported by the Rotary Club of Goslar.

-

School project in Kaolack/Senegal

The Brusch&Ritscher Foundation enables the construction of a school center in Kaolack/Senegal, resulting from a school and town partnership between the Lower Saxony town of Osterode and Kaolack in northwest…

-

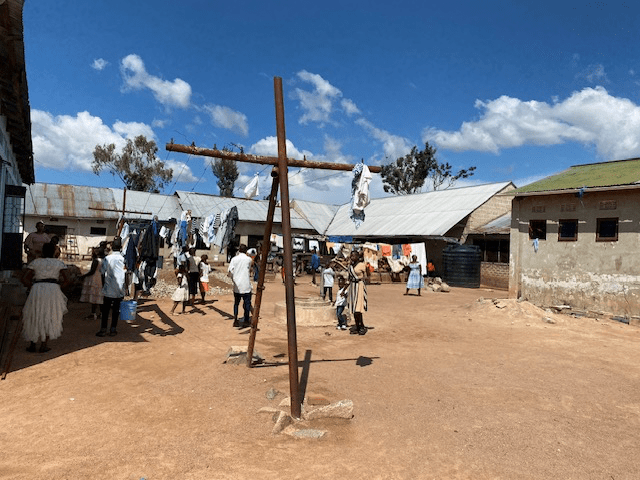

School Project in Bukoba/Tanzania

Tweyambe is a private secondary and high school in the Northwest of Tanzania close to Bukoba. In Spring 2023 the team of VoltaViewAfrica installed a Powerhouse

-

Kibumba Island/Lake Victoria Tanzania

The team from Fraunhofer HHI and Clausthal University of Technology initiated their first project in collaboration with the Tanzanian company JUMEME Ltd. in 2019 at Lake Victoria on the island Kibumba.